Quality control in metal fabrication ensures a product’s integrity, durability, and functionality. At AccuSpec Fabrication, our approach to maintaining the highest standards involves several key strategies.

- Strict Material Selection. We source our metals from reputable suppliers, so every batch meets our stringent purity, strength, and suitability standards. We make high-quality end products because we use superior raw materials. We test our materials for hardness and composition analysis to verify their quality.

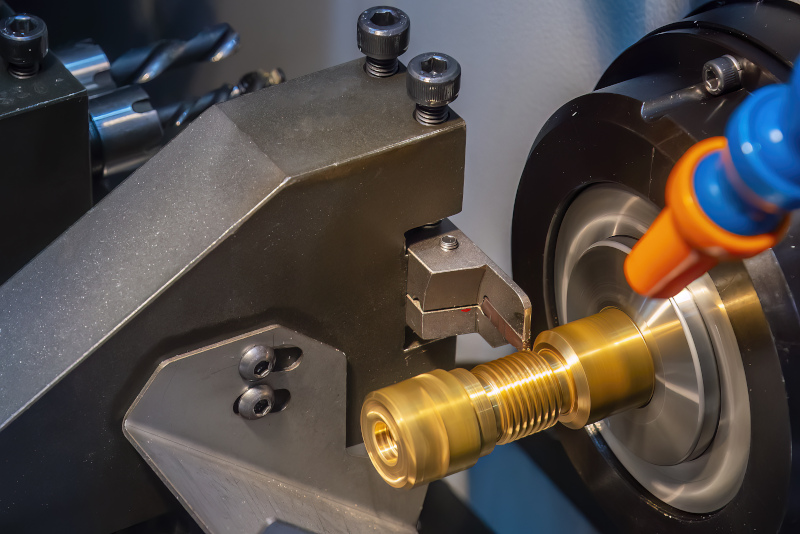

- Advanced Metal Fabrication Techniques. Our facility has CNC machines, precision cutting tools, and advanced welding equipment. These technologies enable us to produce highly precise components.

- Skilled Workforce. Our fabricators, welders, and technicians are selected based on their skills and experience and undergo regular training to stay updated with the latest fabrication techniques. Their meticulous attention to detail and craftsmanship are critical in transforming designs into high-quality metal products.

- Rigorous Testing and Inspection. Testing includes dimensional checks, stress tests, and visual inspections to ensure that every metal fabrication piece meets our high standards. We use manual inspections and automated testing tools to identify defects or deviations from the design specifications.

- Continuous Improvement and Feedback. Embracing a culture of continuous improvement is key to our quality control process. We regularly gather feedback from our clients and frontline workers to identify areas for improvement. This feedback and our commitment to staying updated with industry trends and technological advancements help us refine our processes and maintain a high-quality standard.

We approach quality control in metal fabrication from many angles. Our dedication not only sets us apart in the industry but also ensures the satisfaction and trust of our clients. Contact us today with the details of your next project.