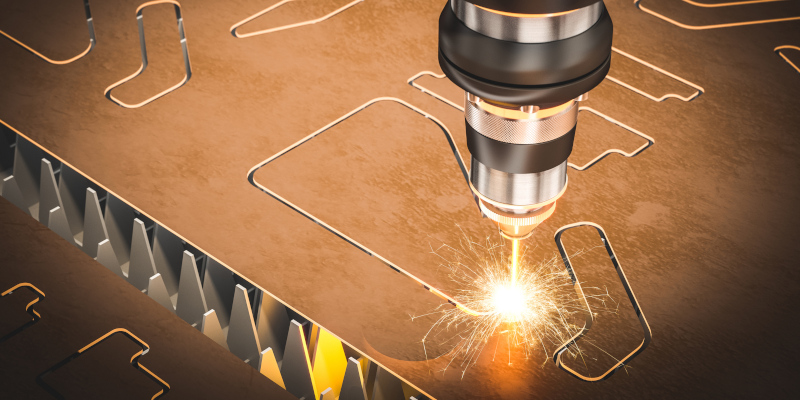

When it comes to fabricating steel components, plasma cutting stands out for its precision and efficiency. But how can you be sure you’re getting top-quality results? Here are some expert tips on what to look for in quality steel plasma cutting.

- Smooth, Clean Edges. The hallmark of quality plasma cutting is smooth, clean edges on the steel. Rough, jagged edges or excessive dross (the residue left from cutting) can be signs of poor technique or inadequate equipment. Look for cuts that are free from burrs and excessive slag, as these can compromise the fit and finish of your components.

- Precise Cuts. Quality steel plasma cutting should precisely follow design specifications without deviation. This is particularly crucial in applications where components need to fit together seamlessly. Inaccurate cuts not only lead to wasted material but can also cause structural issues in the final product.

- Minimal Heat-Affected Zone. Steel plasma cutting generates heat, which can affect the structural integrity of steel. A quality plasma cutting process will minimize the heat-affected zone, reducing the risk of warping or weakening the material.

- Appropriate Cutting Speed. The speed of cutting should be tailored to the thickness and type of steel being used. Speeds that are too fast can lead to incomplete cuts, while too slow speeds can cause excessive heat build-up. A skilled operator will know the optimal speed for each material to ensure the best quality cut.

- Skilled Technicians. The skill and experience of the operators cannot be overstated. Experienced technicians can make fine adjustments in the cutting process, adapting to different types of steel and thicknesses. Their expertise ensures the plasma cutter is utilized to its full potential.

- Proper Safety Measures. Proper safety measures protect not only the operators but also ensure the integrity of the work being conducted. This includes following all industry-standard safety protocols and having a well-organized work environment.

When you assess the quality of steel plasma cutting, it’s important to consider these factors. At AccuSpec Fabrication, we understand these key aspects, so your steel plasma cutting project will be of the highest quality. Contact us today to get your project started.